In the realm of pipe welding, proper preparation is key to achieving strong and reliable welds. One crucial step in the welding process is weld prep beveling, which involves creating a specific angle or bevel on the edges of the pipe joint. In this article, we will delve into the significance of weld prep beveling on pipes, exploring its benefits in terms of weld quality, joint strength, and overall welding performance.

1. Improved Weld Quality:

Weld prep beveling plays a vital role in ensuring high-quality welds. By creating a beveled edge on the pipe joint, the welding process can penetrate deeper into the joint, allowing for better fusion between the base metals. This deeper penetration enhances the integrity and strength of the weld, reducing the likelihood of defects such as lack of fusion or incomplete penetration. The result is a more robust and reliable weld, capable of withstanding the demands of the intended application.

2. Enhanced Joint Strength:

The beveled edges created through weld prep beveling significantly contribute to joint strength. The bevel provides a larger surface area for the weld metal to bond with the base metals, increasing the overall strength and load-bearing capacity of the joint. The wider fusion zone obtained from beveling ensures a stronger connection, minimizing the risk of weld failure and subsequent structural issues. Weld prep beveling is especially critical in applications where pipes are subjected to high pressure, stress, or vibrations.

3. Proper Fit-up and Alignment:

Weld prep beveling also aids in achieving proper fit-up and alignment of pipe joints. By beveling the edges, it allows for better alignment and close contact between the pipes. This ensures that the welding process is performed on clean, properly aligned surfaces, minimizing gaps and ensuring consistent penetration along the joint. Proper fit-up and alignment are crucial for maintaining dimensional accuracy, preventing distortion, and promoting efficient heat distribution during welding.

4. Welding Process Efficiency:

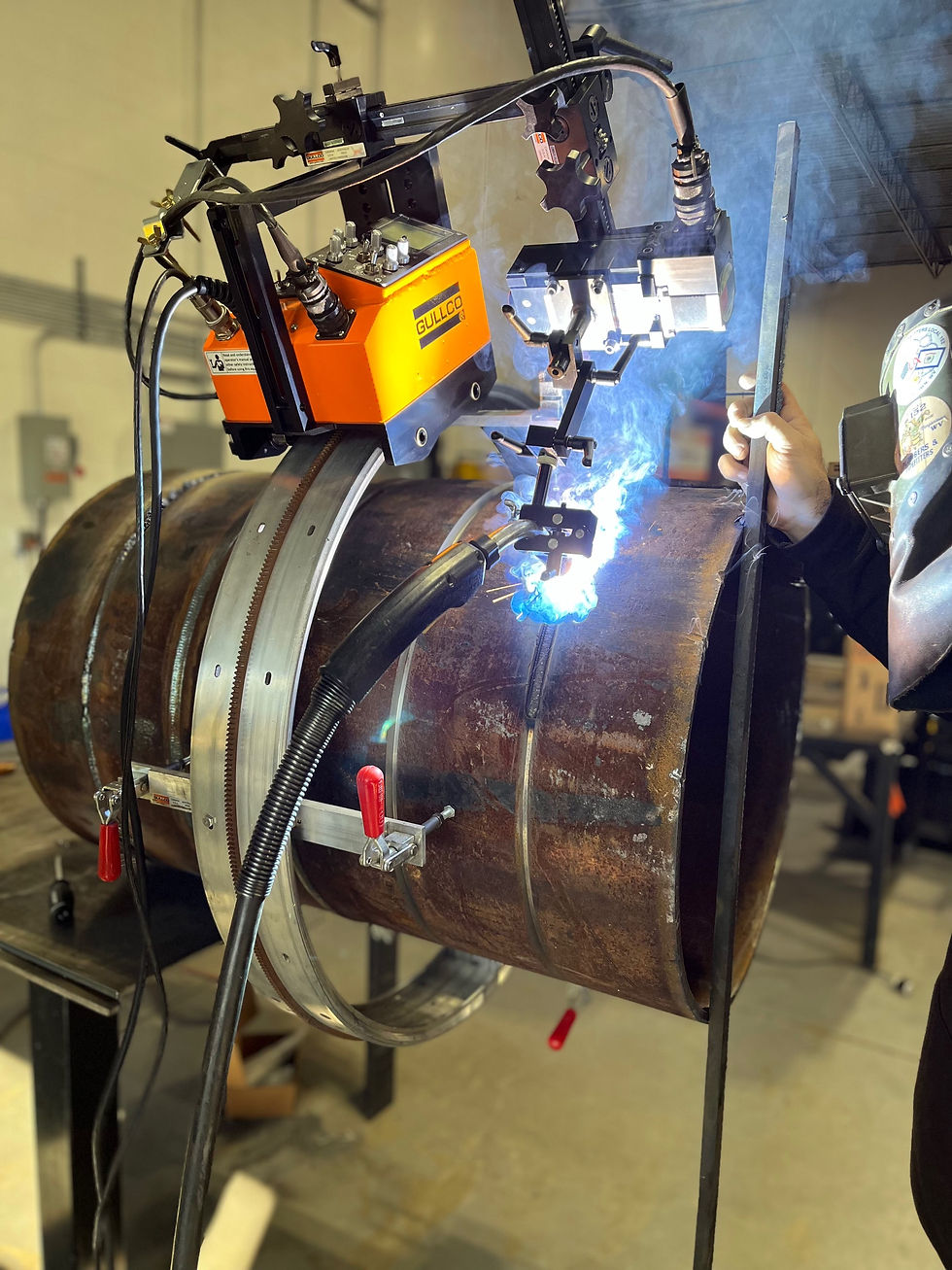

Weld prep beveling contributes to overall welding process efficiency. By beveling the pipe edges, it facilitates easier access for the welding torch or electrode, enabling better control over the welding parameters. The improved accessibility allows welders to achieve optimum arc placement and maneuverability, resulting in smoother and more efficient welding operations. Additionally, the enhanced fusion obtained through weld prep beveling reduces the need for excessive welding passes, saving time, energy, and materials.

5. Compatibility with Various Welding Techniques:

Weld prep beveling is compatible with a wide range of welding techniques, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and flux-cored arc welding (FCAW). Regardless of the welding process employed, the beveled edges facilitate better weld pool control, allowing for precise deposition of filler metal and improved overall weld quality. This versatility makes weld prep beveling an essential practice in various industries, such as construction, oil and gas, and manufacturing.

Conclusion:

Weld prep beveling on pipe joints is a critical step in ensuring high-quality welds, joint strength, and overall welding performance. The beveled edges obtained through this process enable deeper penetration, improved fusion, and stronger connections. By promoting proper fit-up, alignment, and welding process efficiency, weld prep beveling enhances weld quality, reduces the risk of defects, and saves time and resources. As a foundational practice in pipe welding, weld prep beveling is essential for achieving reliable, durable, and structurally sound welds that meet the demands of diverse applications.

Contact us today to explore our extensive machine range for weld prep beveling solutions:

George Ficken

President

GSI Machinery LLC

17351 Hard Hat Dr, Covington, LA 70433

C: (678) 387-7885