Why Automate Your Pipe Welding?

- George Ficken

- Aug 7, 2023

- 2 min read

Updated: Nov 11, 2024

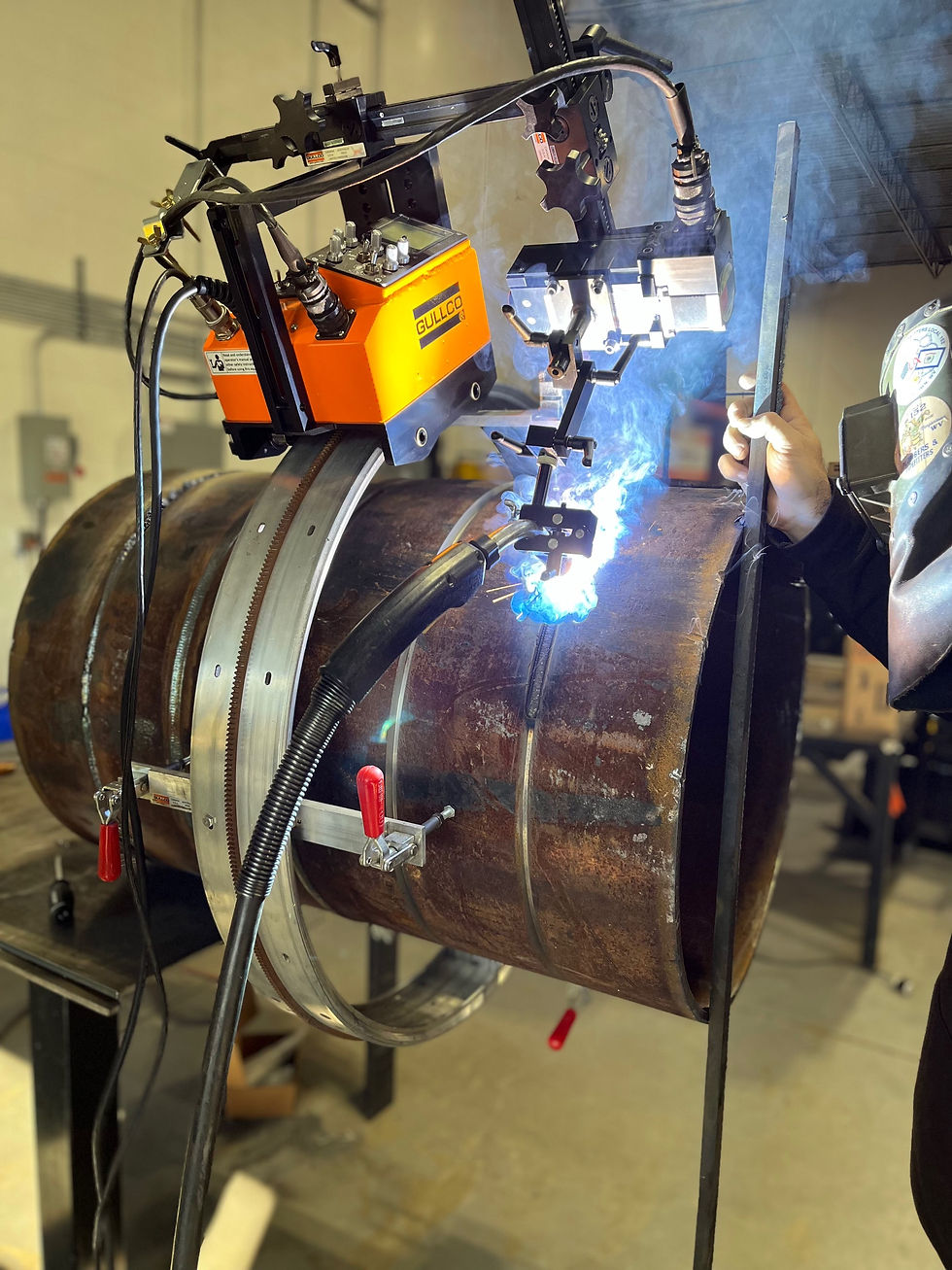

Automating the pipe welding process has emerged as a game-changer for industries that rely heavily on welding operations. From oil and gas to manufacturing and construction, the benefits of automation are evident.

Firstly, automation significantly enhances welding efficiency and accuracy. Automated systems are capable of consistently producing high-quality welds with precise parameters, reducing the risk of human errors that can lead to costly rework. This not only boosts productivity but also ensures the integrity and safety of welded structures.

Secondly, automation leads to a notable reduction in labor costs. Welding is a labor-intensive task that requires skilled operators, and the shortage of qualified welders in many industries can pose a challenge. By deploying automated welding systems, businesses can optimize their workforce and utilize skilled welders for more complex tasks, while leaving repetitive and time-consuming welding to the machines. This not only saves costs but also frees up valuable human resources for other critical areas of the operation.

Lastly, automated pipe welding also promotes a safer working environment. Welding can involve exposure to hazardous fumes, high temperatures, and potentially dangerous working conditions. By automating the process, operators can maintain a safe distance from the welding arc and harmful emissions. This minimizes the risk of welder injuries and improves overall workplace safety. Furthermore, automated systems are equipped with advanced sensors that continuously monitor the welding process, allowing for real-time adjustments and further ensuring quality and safety.

In conclusion, the benefits of automating the pipe welding process are multifaceted and undeniable. Improved efficiency, reduced labor costs, and enhanced safety are just a few of the advantages that businesses can reap from embracing automation. As technology continues to advance, automated welding systems will undoubtedly become an indispensable tool for industries seeking to optimize their operations, stay competitive, and deliver top-notch welded products to meet the demands of the modern market.

GSI Machinery has many pipe and fillet welding automation solutions. If you are interested in learning more to see if our solutions are right for your goals and welding needs please reach out.